In pharmaceutical and personal care manufacturing, packaging integrity plays a crucial role in ensuring product safety, sterility, and compliance. For BFS (Blow-Fill-Seal) containers—commonly used for ampoules, serums, and single-use eyedrops—micro-leaks as small as a few micrometres can compromise product sterility and shelf life.

The BFS Micropore Leak Inspector provides a scientific, non-destructive method to detect even the smallest leaks, enabling manufacturers to verify packaging integrity without damaging the product.

The Industry Challenge: Detecting Invisible Leaks

Traditional leak detection methods, such as vacuum decay or dye penetration, are often limited in accuracy and can cause secondary contamination. They may detect larger leaks but fail to identify micro-defects smaller than 10μm—small enough to escape detection but large enough to allow microbial ingress.

For pharmaceutical companies, this creates serious challenges:

Risk of contamination or product recalls.

Difficulty in meeting GMP and FDA compliance requirements.

Inefficient, destructive testing processes that waste materials.

The Technology Behind Non-Destructive Leak Detection

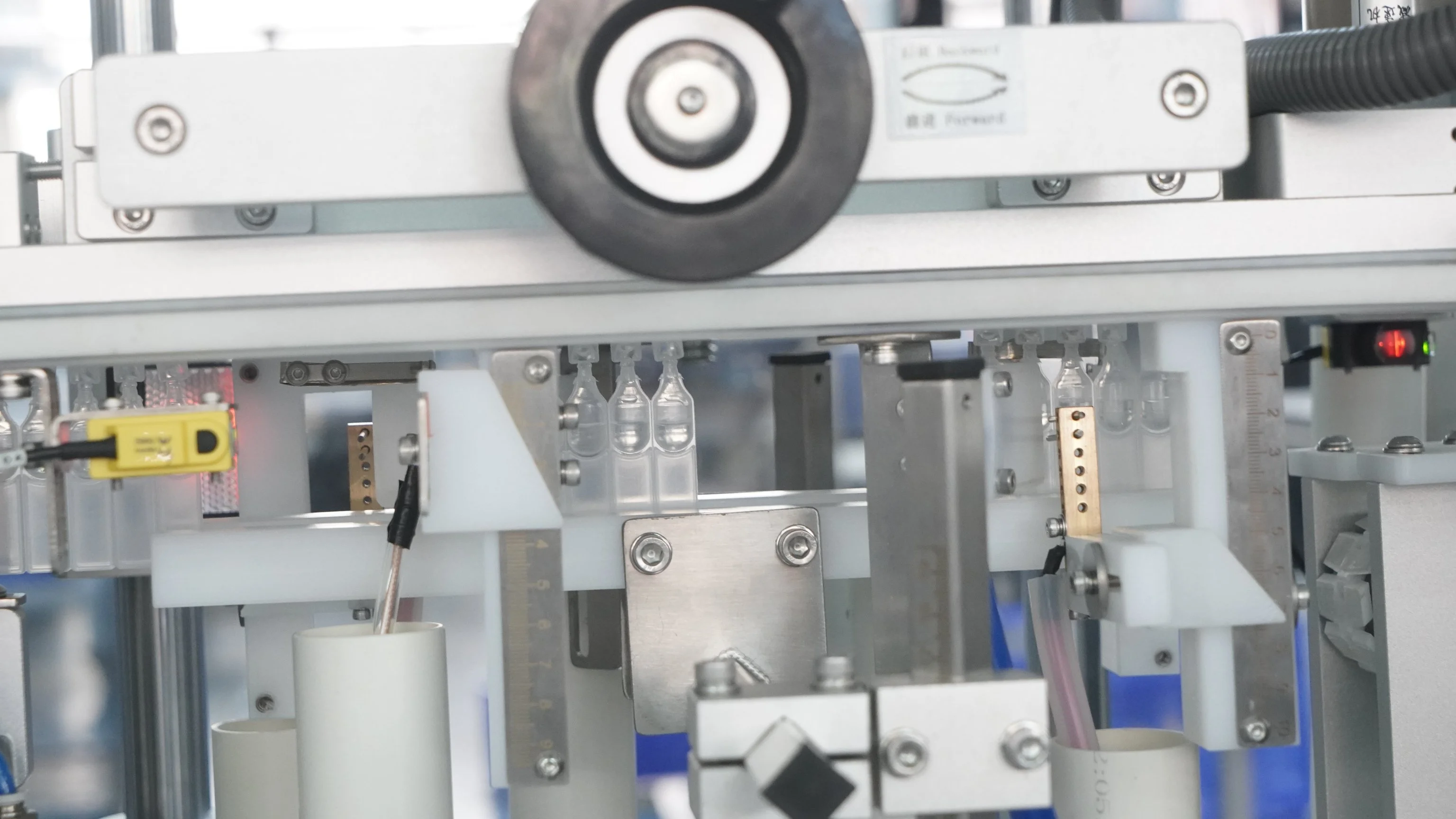

The BFS Micropore Leak Inspector adopts high-voltage discharge sealability testing. Here’s how it works:

High-Voltage Application: A high-voltage, low-current electrical field is applied across the container.

Current Response Monitoring: If the container is perfectly sealed, the electric field does not penetrate the insulating wall.

Leak Detection: When a micro-hole or crack exists, the current passes through the defect into the liquid inside.

Signal Analysis: The system detects the current change and flags the defective bottle automatically.

This technology can identify micro-leaks as small as 5.0 μm, far beyond the resolution of traditional vacuum methods.

Advantages for Pharmaceutical Production

Non-Destructive and Clean: No use of dyes or liquids, avoiding secondary contamination of the product.

High Sensitivity: Detects minute leaks that would otherwise go unnoticed.

Safe for BFS Containers: The low energy applied prevents damage to delicate plastic strip ampoules.

Reliable Quality Control: Fully automated testing ensures consistent and repeatable results.

Applications Across the Industry

This system is ideal for pharmaceutical enterprises producing BFS packaging such as:

Single-use ampoules and vials.

Cosmetic serum bottles.

Small-volume parenteral or ophthalmic solutions.

It can also support high-speed inspection lines, offering scalability from laboratory validation to full production.

Conclusion

For enterprises adopting BFS technology, ensuring the integrity of every ampoule is essential. The BFS Micropore Leak Inspector represents a significant step forward in non-destructive quality assurance—combining precision, safety, and automation.

As regulatory demands grow stricter, investing in intelligent leak detection technology is not just about compliance—it’s about protecting brand trust and product reliability.